ANTI-FIRE SOLUTION

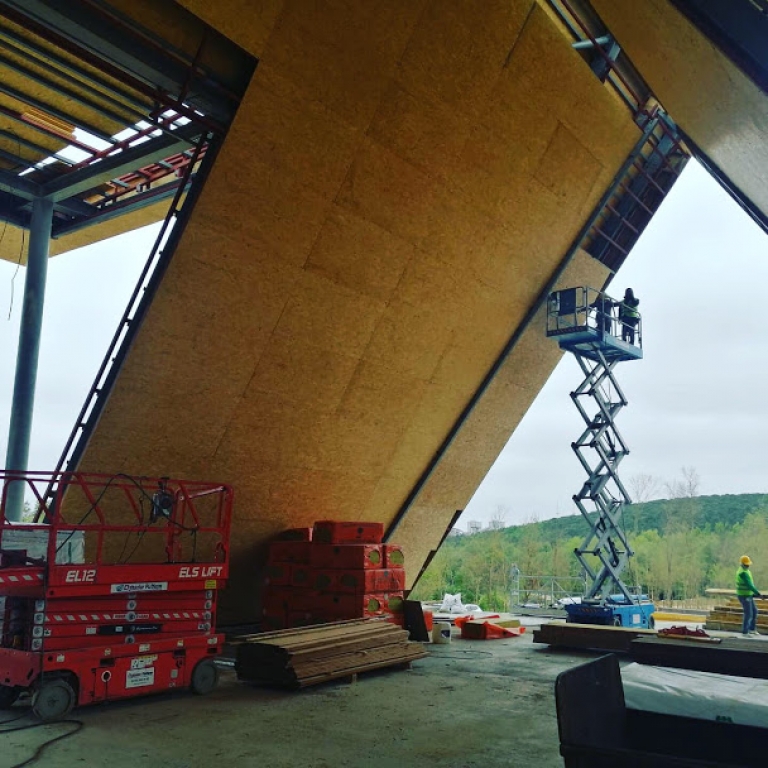

ISONEM ANTI FIRE SOLUTION, the non-flammable solution encapsulates the applied surface as molecules and prevents its contact with oxygen. Thanks to its active ingredients, it prevents it from reaching the temperature that will initiate the combustion reaction. In this way, the substance to which it is applied never catches fire. This product has been tested on a plywood wooden door. The 14mm thick plywood door with 1500 ° C heat applied to the front was exposed to direct flame for 40 minutes, at the end of this period it was found that the rear face only increased to 120°C. It has been observed that the wooden plywood door never catches fire.

ISONEM ANTI-FIRE non-flammability solution is a product that is produced from 100% natural materials, has no harm to human health, is 100% soluble in nature, and does not contain any prohibited materials. The smoke of a substance treated with a non-flammability solution contains 50% less carbon dioxide and carbon monoxide than the natural state of the same substance. In addition, it is 20-25% richer in terms of smoke and nitrogen. Therefore, while the surface is not flammable, the suffocating effect of its smoke has been reduced by half. It is water based, one component.

WHAT MAKES ISONEM ANTI FIRE NON-FIRE SOLUTION UNIQUE?

ISONEM ANTI-FIRE non-flammability solution is not a flame retardant, it provides a complete non-flammability. The flame retardant applied material (textile, wood, etc.) burns when it is exposed to the flame and goes out when the flame is cut off. In other words, the main thing is that the substance does not burn when it is removed from the flame source. This can slow the spread of a fire, but it will never prevent it. The substance applied with ISONEM ANTI-FIRE non-flammability solution does not catch fire.

According to TSE TEST AND INSPECTION REPORT:

- INSPECTION AND EXPERIMENTS ARE DONE ACCORDING TO TS EN ISO 1716: 2010/JANUARY 2011.

- According to TS EN ISO 1182 /02.02.2012 DATE/ 139913 NO., in the result of the inspection and experiments, approved to CLASS A1 according to the criteria EN 13501-1/JANUARY-1 CHART-1.

TEST RESULTS ACCORDING TO IZMIR INSTITUTE OF TECHNOLOGY BIOLOGY DEPARTMENT RESEARCH LABORATORY

THE MATERIAL RESPONSE APPLICATION: Paper - Sponge - Wood – Fabric – Cotton

RESULT: NO BURNING

CONCLUSION

No burning, glare, melting activity has been observed in the relevant materials except for growing dark, and as a result, it has been shown that this liquid can be used effectively against combustion events.

TECHNICAL SPECIFICATIONS

Documents of the Product

Documents of the ProductISONEM ANTI-FIRE SOLUTION USAGE AREAS and METHODS

For wood materials: It can be made by waiting in the pools, depending on the absorption (absorption) of the wood or by spraying on the wood. If it is compatible with the paste by testing on MDF and chipboard, it is used in its production at the first stage. If the method of holding is done in the pool, one day at most is sufficient. Half an hour is enough for chipboard and MDF. According to the hardness of the wood, it has an incombustibility absorption capacity.

For the paint industry: It is incompatible with the paint itself. Since the target paint is not burnt, the application method is as follows; Before painting or varnishing, sanding will be done and then ANTI-FIRE non-flammability liquid is applied immediately before painting and dried, it is absolutely necessary to dry. Painting is done after this process takes place.

For industry sector: Fabric, cotton, wool, sponge, etc. In absorbent materials, it is made non-flammable and non-flammable by wetting with ANTI-FIRE, squeezing and then drying.

COLOR: Slight blurred

CONSUMPTION: It varies according to the application and application surface. Consumption amount should be determined by pretesting according to the absorbency of the application surface or material. (0.2 - 0.3 kg/m²)

PACKING: 5L PE Plastic can

SHELF LIFE: 24 months from date of production if stored in original, unopened, undamaged packages.

STORAGE CONDITIONS: Store tightly closed in a dry and cool (5 - 35°C) place.

IMPORTANT: The surface should be protected from rain, water, mechanical loads and impacts for 24 hours during and after the application.

Français

Français Español

Español русский

русский العربية

العربية Deutsch

Deutsch